Automatic Steering System

Core components: controller, tablet, steering motor, front wheel sensor, gnss antenna

This system is suitable for various agricultural operations such as plowing, harrowing, ridging, seeding, inter-row cultivation, spraying, harvesting, etc.

It assists agricultural machinery operators, improves operational accuracy and efficiency, and significantly reduces the workload and intensity of the operators.

Product Introduction:

The automatic steering system is designed for four-wheel agricultural machinery (tractors, self-propelled harvesters, etc.).It can replace the manual steering behavior of the operator by controlling the steering, enabling the agricultural machinery to automatically drive along a preset route.

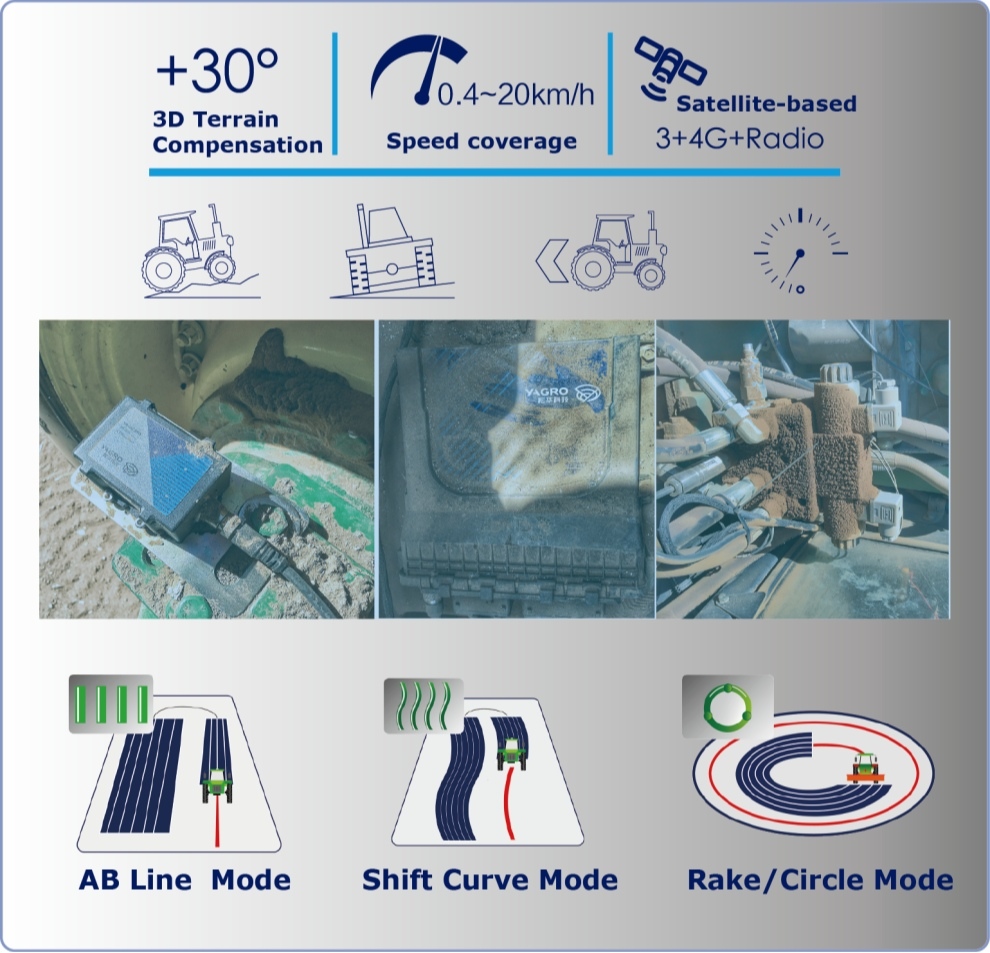

It can simultaneously receive signals from GPS, Galileo, Beidou and GLONASS satellites. It utilizes RTK high-precision satellite positioning technology to achieve centimeter-level accuracy in the position of the agricultural machinery. Using inertial navigation, automatic control, and electric steering, the system controls the steering wheel to guide the agricultural machinery, achieving automatic operation along specified routes with an accuracy of up to ±2.5cm.

This system is suitable for various agricultural operations such as plowing, harrowing, ridging, seeding, inter-row cultivation, spraying, harvesting, etc. It assists agricultural machinery operators, improves operational accuracy and efficiency, and significantly reduces the workload and intensity of the operators.

Core Components:

1. Controller

Controller serves as the "eyes" and "brain" of the entire system. Its high-precision satellite positioning device receives satellite signals and correction information sent by reference stations simultaneously, achieving high-precision vehicle positioning (using RTK positioning technology with a precision of 2~3cm). The vehicle's attitude and direction information are determined by the internal vehicle attitude sensor and front wheel sensor. The electric steering wheel is controlled based on the preset route to achieve precise vehicle steering, allowing the vehicle to travel along the predetermined route.

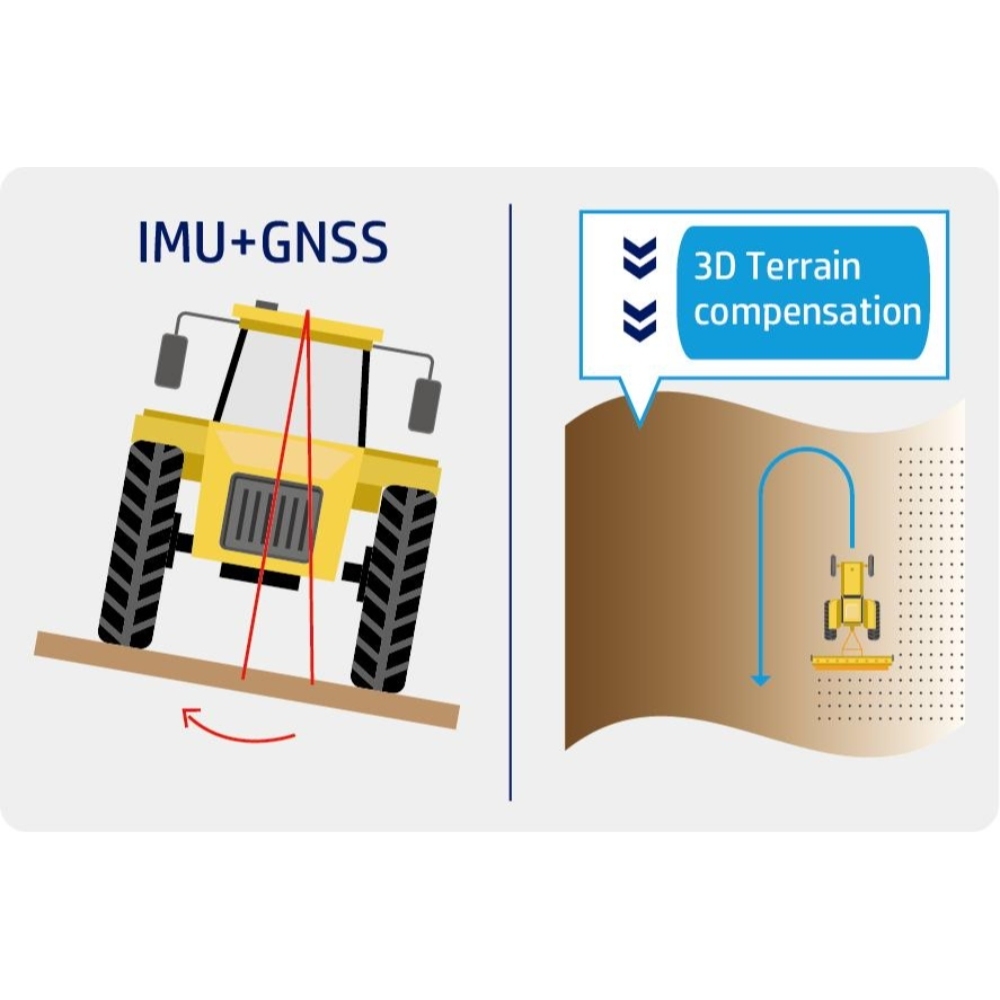

Controller is equipped with a high-precision IMU (Inertial Measurement Unit) sensor, which, through high-frequency integrated navigation computation with GNSS, achieves 3D terrain compensation algorithms. This ensures excellent control accuracy for operations on sloping terrains, undulating terrains, and slopes, even when the slope angle exceeds 30° or the operating speed exceeds 15 km/h. The system can maintain a control accuracy of 2.5cm and achieve precise turning during these challenging conditions.

2. Tablet

The tablet features a robust 10-inch high-definition display, with an IP67 protection rating, making it resistant to rain and snow. It comes with a built-in 4G wireless module, WiFi/Bluetooth modules, RS232 interface, USB interface, and CAN bus interface.

The software operation and interaction are smooth and coherent, offering users a seamless experience. The field mapping and trajectory refresh rate can go up to 100Hz, providing users with greater convenience in land management. This high refresh rate not only brings significant convenience to field management but also greatly reduces user fatigue during prolonged use, enhancing the overall user experience in human-computer interaction.

The auto steering motor is a brushless DC torque motor that supports both 12V and 24V power systems. It has a peak torque of up to 20Nm and a rated torque of 6Nm. Specifically designed for agricultural machinery usage scenarios, it meets various requirements such as vibration characteristics, three-proof features (rainproof, dustproof, and salt spray resistance), and temperature characteristics, all reaching the automotive-grade standard.

Additionally, it is internally integrated with a high-precision position encoder, significantly enhancing control accuracy and response speed. The motor features fault code prompts, over-current and overload protection, over-voltage and under-voltage protection, temperature protection, and short-circuit protection. In continuous navigation operations, it greatly extends the battery life, thus protecting the vehicle's power supply system.

4. Front Wheel Sensor

The front wheel steering angle sensor is an optional accessory that utilizes an inertial sensor for measurement. It requires no maintenance or calibration, as it automatically estimates the gap and errors in the tractor's front wheels in real-time during each startup, eliminating them within the system.

Once installed, it enhances operational speed and control stability, making it particularly suitable for high-speed operations with high-horsepower tractors (speeds exceeding 10km/h). It has an IP67 protection rating, making it resistant to rain, wind, and dust.

5. GNSS Antenna

The satellite antenna is capable of simultaneously receiving signals from the GPS, Galileo, GLONASS, and BeiDou satellite systems. It enables Precise Point Positioning (PPP), achieving centimeter-level positioning even in the absence of a differential correction link. The system is designed to operate with a single antenna, eliminating the need for the complexities associated with the installation and calibration of dual antennas.

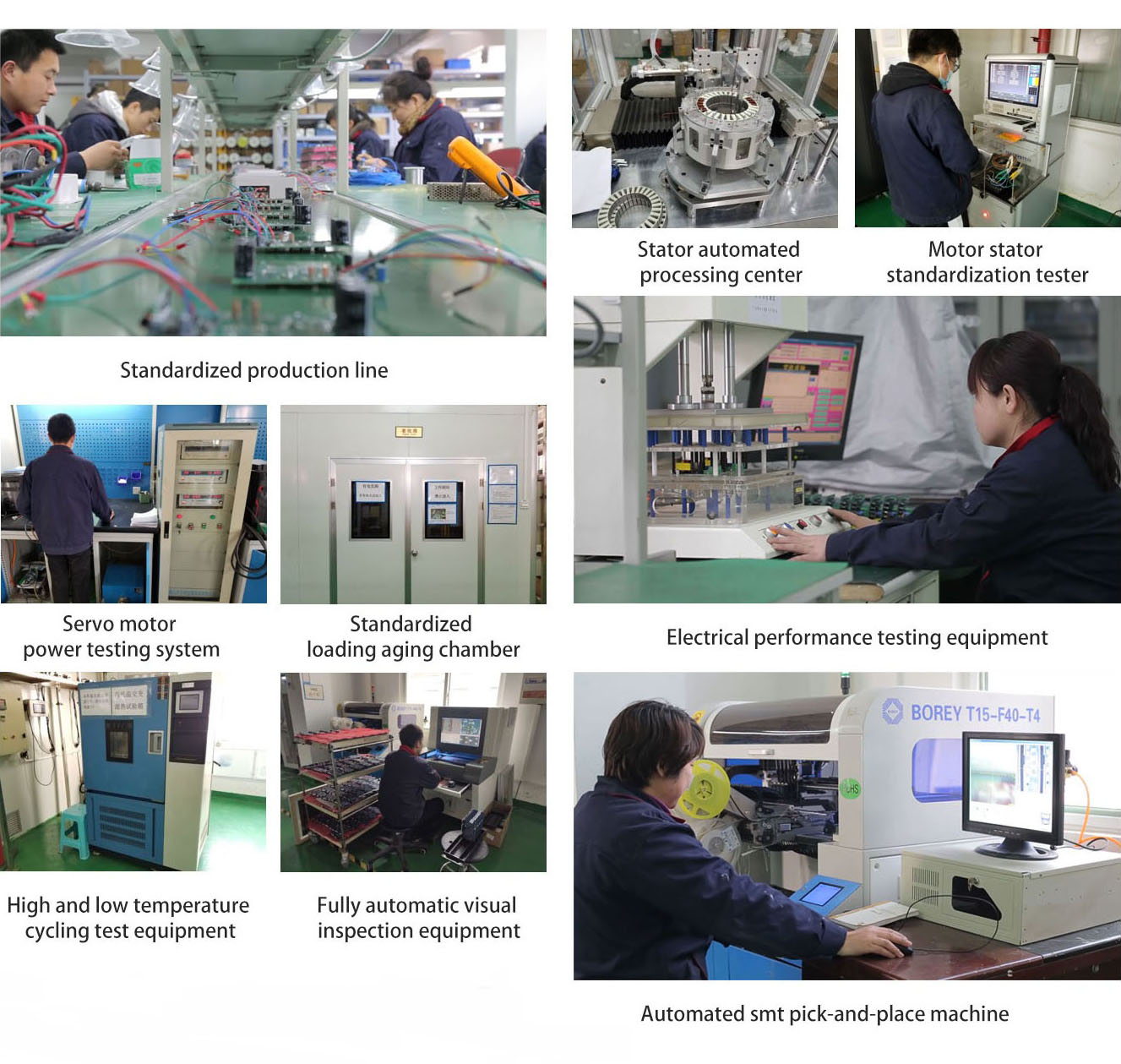

Advanced Equipment&Workshop: