What Are the Precautions Associated With Outdoor Robot Platforms?

The four-wheel drive and four-wheel steering chassis RMP-WL300 is a mobile robot chassis specially developed for the agricultural field. It is designed with an adjustable wheel track and wheelbase structure, solving the pain point of inconsistent ridge spacing in planting areas. Meanwhile, the outdoor robot platform is equipped with a built-in VCU controller, providing CAN communication protocol, which can be matched with various navigation methods such as Beidou, laser, and following, achieving efficient autonomous navigation and unmanned operation.

To ensure the efficient and stable operation of the RMP-WL300 wheeled chassis, fully leverage its performance in large load capacity and rapid secondary development, and extend its service life, please follow the following precautions and regular maintenance inspection items.

Precautions

1. This device must be used with its designated charger. Other chargers or batteries must not be used, as they may cause battery damage.

2. Do not store the device in a damp, dusty or overheated environment. Avoid placing liquids on the four wheel drive chassis. Regularly wipe it to keep the equipment clean. It is also necessary to regularly remove oil stains, rust and other residues, and apply lubricants to easily worn mechanical parts.

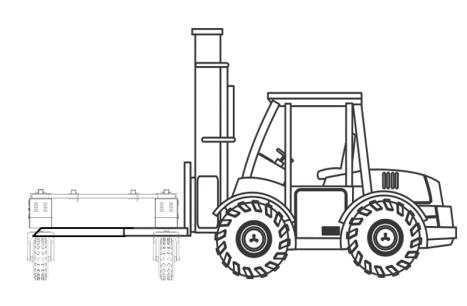

3. Do not operate the vehicle in sandy or desert environments. When moving the vehicle manually, use a forklift as shown in the figure below.

Please adjust the fork spacing first to match the width of the 4 wheel drive robot chassis. Then place the forklift forks under the chassis and lift the forklift forks to lift the chassis off the ground smoothly. Wait until the equipment has fully risen before moving the forklift. It is strictly prohibited to move the equipment by means of towing or dragging, etc., to avoid damaging the structure and appearance of the vehicle body.

4. Charge the equipment when the battery level drops below 30% after operation to prevent insufficient power from affecting performance during the next use.

5. Regularly inspect all bolts and nuts for looseness and adjust them to the proper tightness as needed.

6. Periodically check the tires for severe wear. If significant wear is found, replace the tires immediately to ensure normal operation of the equipment.

7. A comprehensive inspection of the four wheel drive chassis should be carried out after one year of continuous use. Focus on checking whether there is any wear at the joints of each rotating shaft of the equipment.

8. When fully charged, verify that the battery's endurance time is normal.

9. During daily use, pay attention to abnormal sounds, persistent vibrations, or continuous overheating during operation. If any issues are detected, address them promptly or report them to the manufacturer.

10. Non-technical personnel are not allowed to disassemble or modify the electrical layout, circuits, functions, etc. of the robot without authorization.

Maintenance Checklist

1. Perform maintenance every 30 days.

2. Check that the emergency stop button and power switch on the control panel function properly.

3. Inspect the main load-bearing fastening points of the mechanical structure for abnormalities.

4. Check all mechanical connection points for looseness.

5. Check tires for severe wear. Contact us for replacement if significant wear is found to ensure normal operation.

6. After one year of continuous use, thoroughly inspect all rotating shafts and joints for wear.。

7. Verify the battery's runtime is normal when fully charged.

8. Check the robot's battery and manual charger status comprehensively to ensure proper function.

9. During daily use, monitor for abnormal sounds, persistent vibrations, or continuous overheating during operation. If any problems are found, contact the outdoor robot chassis supplier in a timely manner for resolution.

10. Only technical personnel authorized by our company are permitted to disassemble, modify the electrical layout, wiring, or functions of this robot. Unauthorized alterations are strictly prohibited.

The four-wheel drive and four-wheel steering outdoor robot platform RMP-WL300 is widely applicable to various agricultural scenarios such as field plant protection, mechanization transformation of orchards, and construction of unmanned farms. Its flexible and mobile design provides reliable support for improving the quality and efficiency of modern agricultural production. Correct use and regular maintenance and inspection are important guarantees for giving full play to the performance of the wheeled chassis and extending its service life. Manda Intelligent focuses on the research and development, production and sales of agricultural robots and robot chassis, and is committed to providing customers with customized products and complete technical solutions. Empowering agriculture with technology and laying a solid foundation for comprehensively enhancing operational efficiency and management quality through high-performance robot chassis.

If you have any questions or needs during use or maintenance, you are welcome to obtain more information or technical support through the following methods:

Official Website: https://www.mandarobot.com/

Email: sales@mandarobot.com