Outdoor Robot Chassis

RMP-BL100

Explosion-proof body structure design, suitable for class II explosion-proof areas

Sufficient reserved space for external equipment installation, enabling simpler layout design

360° precise control with flexible maneuverability

High-perference environmental adaptability, with low-tempeture resistance down to -40℃.

Can be equipped with Beidou, laser, and other navigation systems.

Four wheel double fork arm independent suspension structure, superior shock absorption performance

Built-in VCU supporting rapid secondary development

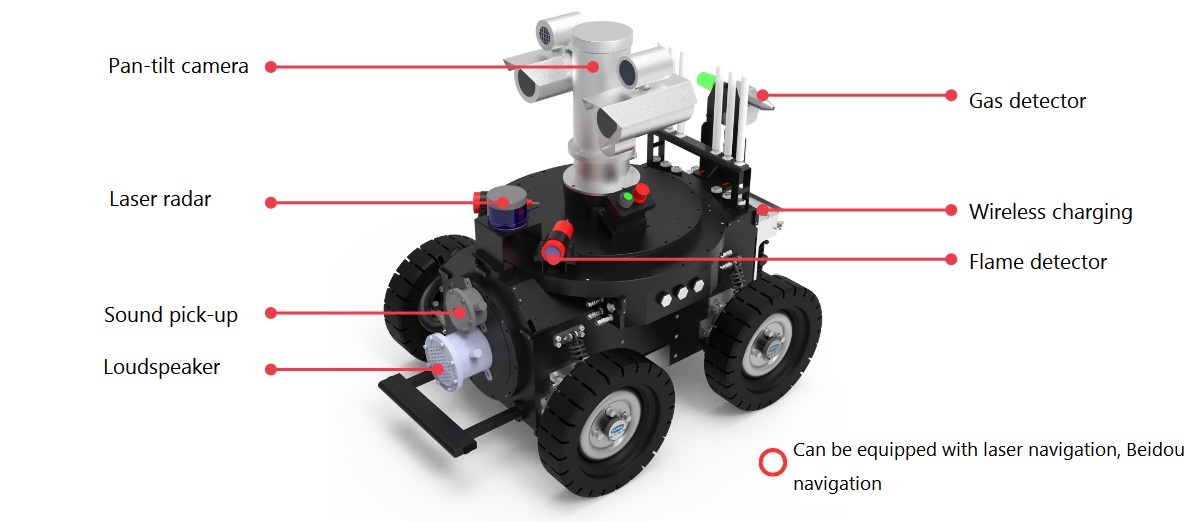

Product Description:

The RMP-BL100 explosion-proof wheeled chassis is a mobile platform specially designed for high-risk and explosive environments such as inspection and firefighting. It has strong passability and flexibility, and can adapt to various complex terrains. In explosion proof robots, the chassis is one of its core components. The RMP-BL100 outdoor robot chassis has a maximum load capacity of 150kg and can climb up a 20° slope. It is equipped with four independent double wishbone suspension shock absorption systems externally, which can effectively buffer impacts and easily handle complex industrial road conditions such as speed bumps and gravel roads.

1. The four wheeled chassis adopts an overall explosion-proof design and is suitable for flammable and explosive sites of Class IIC. It has passed the inspection of Nanyang Explosion-proof Electrical Research Institute and obtained explosion-proof certification, ensuring the safety of operations in hazardous environments.

2. The outdoor robot chassis is driven by 4 independent servo motors, with a load capacity of up to 150kg. Equipped with 4 sets of double fork arm independent suspension structures, it can effectively buffer road impact, easily handle various complex road conditions such as paved roads and speed bumps, and provide a stable operation foundation for the carried equipment.

3. Reserve electrical interfaces and mechanical installation holes for PTZ cameras, loudspeaker, sound Pick-up, gas detectors, wireless chargers and other equipment, allowing users to easily expand. Meanwhile, it is equipped with a standardized CAN communication VCU that supports secondary development, significantly shortening the R&D cycle and enabling scientific research and industry users to efficiently achieve customized functional expansion.

4. The remote control platform has undergone rigorous tests such as vibration and jolting, high and low temperatures, rain exposure and explosion experiments. Its structural strength and environmental adaptability have been fully verified, providing a solid guarantee for stable and reliable operation under harsh working conditions.

Parameters:

Description | Specification | Description | Specification |

Model | RDR-Z150BL-M3 | Steering type | Four-wheel differential |

Dimensions | L1250×W900×H620mm±50mm | Total weight | 430kg±30kg |

Speed | 0~4.5km/h | Run time | 5.5h |

Obstacle negotiation height | ≤100mm | Climbing angle | 20° |

Ground clearance | 100mm±20mm | Rated load | 150kg |

Turning diameter | 1400mm±100mm | Suspension | The two forks are suspended independently |

Tyre | Diameter 400 x width 100mm solid tire | Obstacle avoidance form | Ultrasonic,anti-collision strip, laser (optional) |

Explosive-proof grade | Ex db ib IIC T6 Gb | IP Grade | IP66 |

Operation | Hand held remote control | Remote control distance | 50m(clear sight distance) |

Charging time | 4h(Can reach 80% battery capacity) | Charge | Manual/wireless charging |

Battery Parameter | DC48V lithium iron phosphate battery | Working temperature | -20℃~+55℃ |

Brake mode | Electromagnetic brake | Communication interface | CAN |

Charge Pile | Wireless charging pile (optional) | ||

Navigation | Can be equipped with laser navigation, Beidou navigation | ||

Application:

It is mainly applied in operation fields with explosion-proof requirements such as petrochemical, natural gas plants, disaster relief and exploration.

Certificate:

To ensure stable product quality and precisely meet the requirements of the international market, Manda Intelligent has established a comprehensive standardized management and production system and has passed the ISO9001:2008 international quality management system certification. Meanwhile, products such as wheeled chassis and explosion-proof inspection robot chassis have obtained multiple explosion-proof qualification certificates and test reports issued by national and international authoritative institutions.

Advanced Equipment&Workshop:

In the R&D stage, mainstream simulation software is used to identify and prevent potential risks. In terms of quality control, a complete quality management system has been established, strictly implementing the full-process control from problem traceability to improvement closed-loop, and continuously promoting the PDCA cycle optimization. Through testing equipment such as aging test rooms, high and low temperature test chambers, and motion simulation systems, the stability and reliability of product quality are ensured.