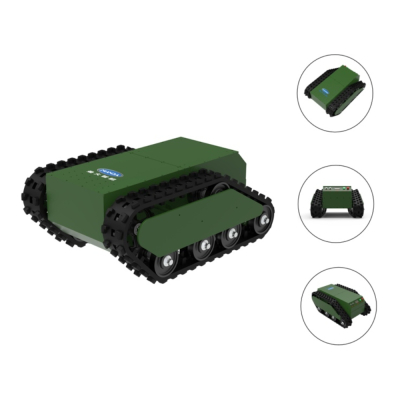

Wheeled Robot Platform

RMP-BL200

Compact chassis design with ultra-low energy consumption

Compact and flexible, adaptable to narrow industrial spaces.

4-wheel independent drive with powerful-power output

Explosion-proof body structure design, suitable for class II explosion-proof areas

Built-in VCU supporting rapid secondary development

Product Description:

The power of the RMP-BL200 explosion-proof wheeled robot platform is driven by four independent servo motors and planetary reducers. It can support a maximum load of 100kg and climb a 20° slope. The steering mode is differential operation. The entire structure is made of corrosion-resistant aluminum alloy material, featuring light weight and corrosion resistance.

1. Robot chassis adopts whole explosion-proof design concept, their level of explosion-proof applies to all dust and flammable and explosive place IIC, ensure the safe and stable operation in all kinds of high-risk places. The wheeled chassis has undergone strict inspection and certification by Nanyang Explosion-proof Institute and obtained the corresponding explosion-proof qualification certificate.

2. The width of the wheeled robot chassis is less than 600mm, which has excellent space passability, and can flexibely shuttle through the narrow passages and working areas common in factories, warehouses, laboratories and so on. The chassis box is made of aluminum material, which is lightweight and has strong corrosion resistance, thus extending the service life of the equipment.

3. The robot platform reserves electrical interfaces and mechanical installation holes for devices such as pan-tilt cameras, loudspeakers, sound pick-ups, gas detectors, and wireless chargers, allowing users to easily expand. It is also equipped with a built-in standard CAN communication VCU, facilitating users' secondary development.

4. To ensure absolute reliability in extremely harsh environments, the explosion-proof robot platform has undergone multiple rigorous tests, including vibration and jolting tests, high and low temperature tests, rain tests, and explosion tests. At the same time, its protection level reaches IP66, which together form a solid foundation for its stable operation in complex and high-risk scenarios.

Parameters:

Description | Specification | Description | Specification |

Model | RDR-Z100BL-M1 | Steering type | 4WD differential |

Dimensions | L1000×W580×H520mm±50mm | Total weight | 230kg±30kg |

Speed | 0~4.3km/h | Run time | 5.5h |

Obstacle negotiation height | ≤50mm | Climbing angle | 20° |

Ground clearance | 85mm±10mm | Rated load | 100kg |

Turning diameter | 1400mm±100mm | Suspension type | None |

Tyre | Diameter 320 x width 80mm solid tire | Obstacle avoidance | Anti-collision strip |

Explosive-proof grade | Ex db ib IIC T4 Gb | IP Grade | IP×6 |

Operation | Handheld remote control | Remote control distance | 50m(clear sight distance) |

Charging time | 3h( to reach 80% battery capacity) | Charging | Manual/wireless charging |

Battery Parameter | DC48V lithium iron phosphate battery | Working temperature | -20℃~+55℃ |

Brake mode | Electromagnetic brake | Communication interface | CAN |

Charge Pile | Wireless charging pile (optional) | ||

Navigation | Can be equipped with laser navigation, Beidou navigation | ||

Application:

The explosion-proof wheeled robot platform is mainly applied in flammable, explosive and dusty environments with explosion-proof requirements, for operations such as inspection, fire fighting, disaster relief and exploration. For example: petrochemical industry, natural gas plants, open-pit coal mines, etc. It can replace or assist humans in entering dangerous areas to carry out tasks, fundamentally ensuring personnel safety.

Certificate:

Manda Intelligent, guided by meeting market demands, has effectively guaranteed the stability and reliability of product quality by comprehensively implementing the standardization of management and products. The company's products have been certified by national and international authoritative institutions and have obtained multiple explosion-proof qualification certificates and test reports.

Advanced Equipment&Workshop:

In terms of quality control, we have established a systematic management mechanism. Through the product quality control system, we have achieved full-process quality monitoring from raw material warehousing to finished product delivery. While emphasizing quality inspection during the product production process, we also trace the root causes of existing quality issues and establish an improvement closed loop from problem discovery to measure implementation. The testing equipment equipped includes aging test rooms, high and low temperature experimental equipment, motion simulation equipment, etc. Through a comprehensive control system, the stability and reliability of product quality are ensured.