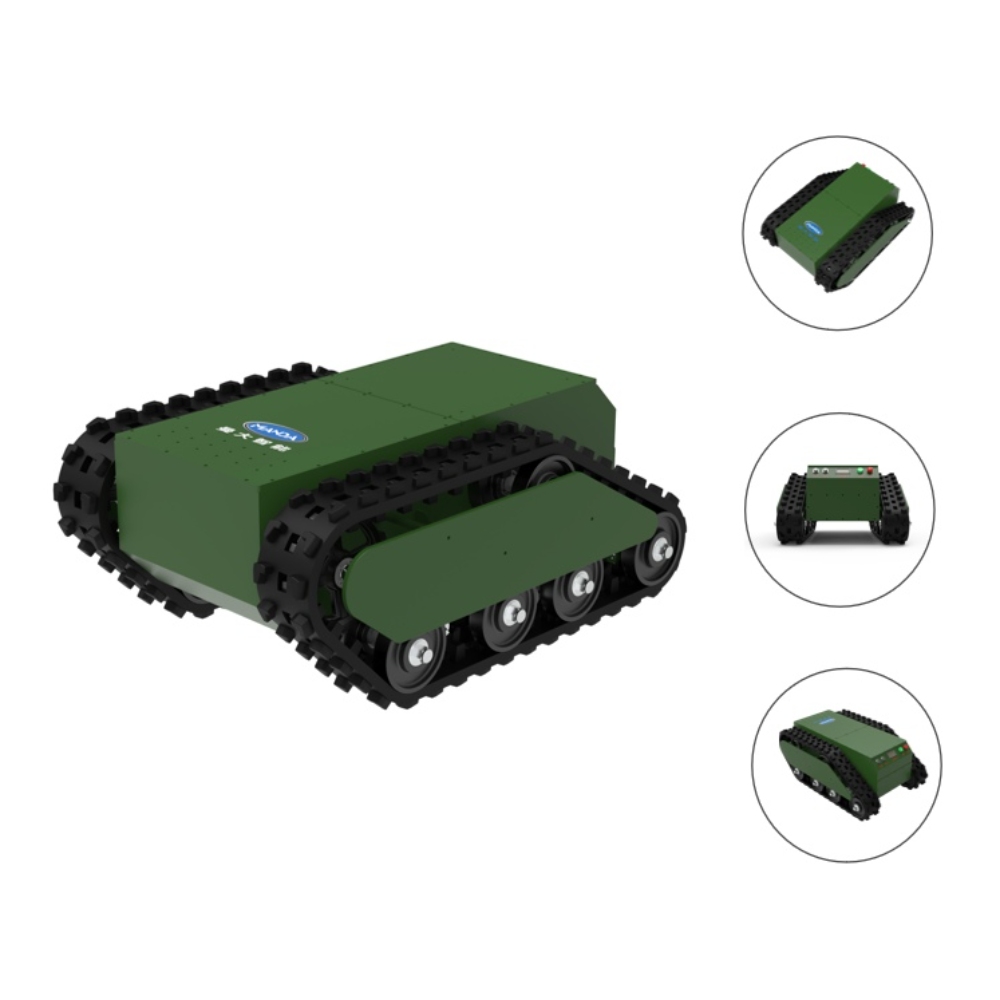

Tracked Robot Platform

Miniaturized design, excellent pass-ability

Independent track suspension, compact structure, lower operation cost

High speed driving performance, with a maximum speed of 15 km/h

Compact structure, precise control, suitable for relatively high speed

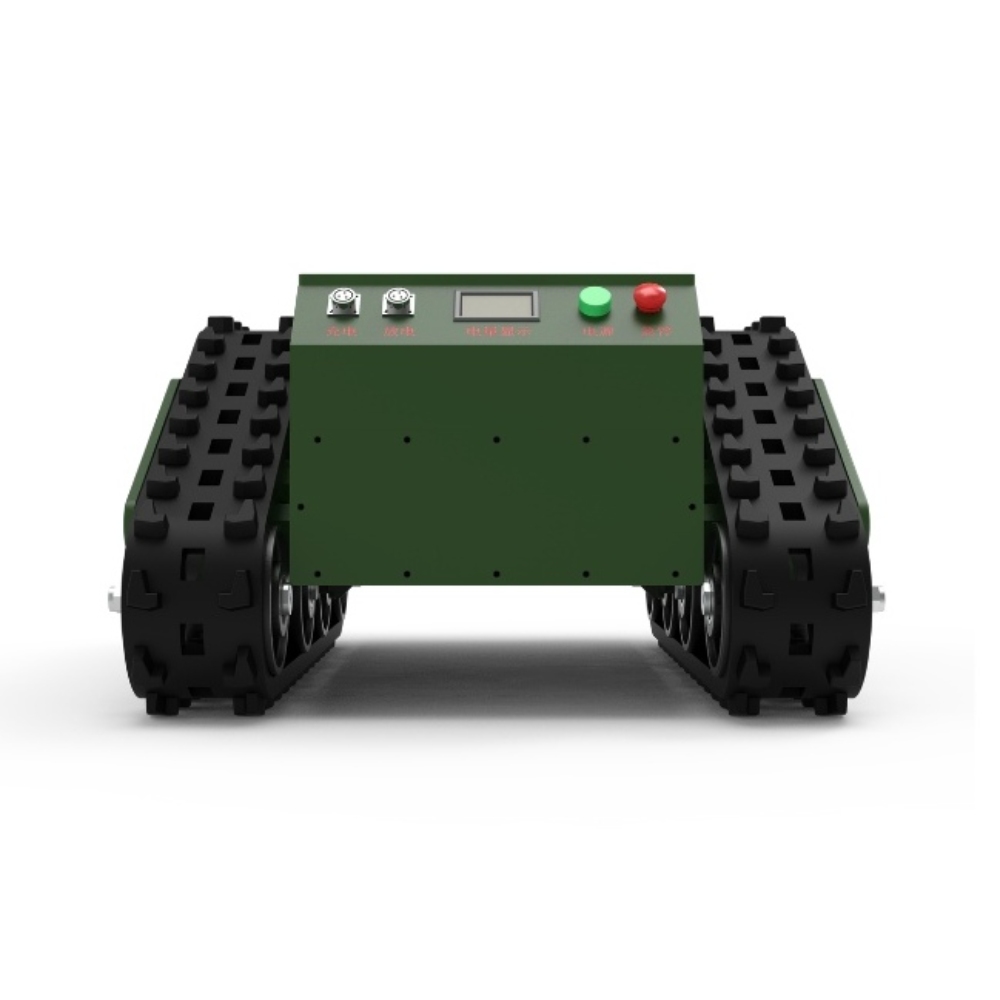

Built-in VCU supporting rapid secondary development

Product Description:

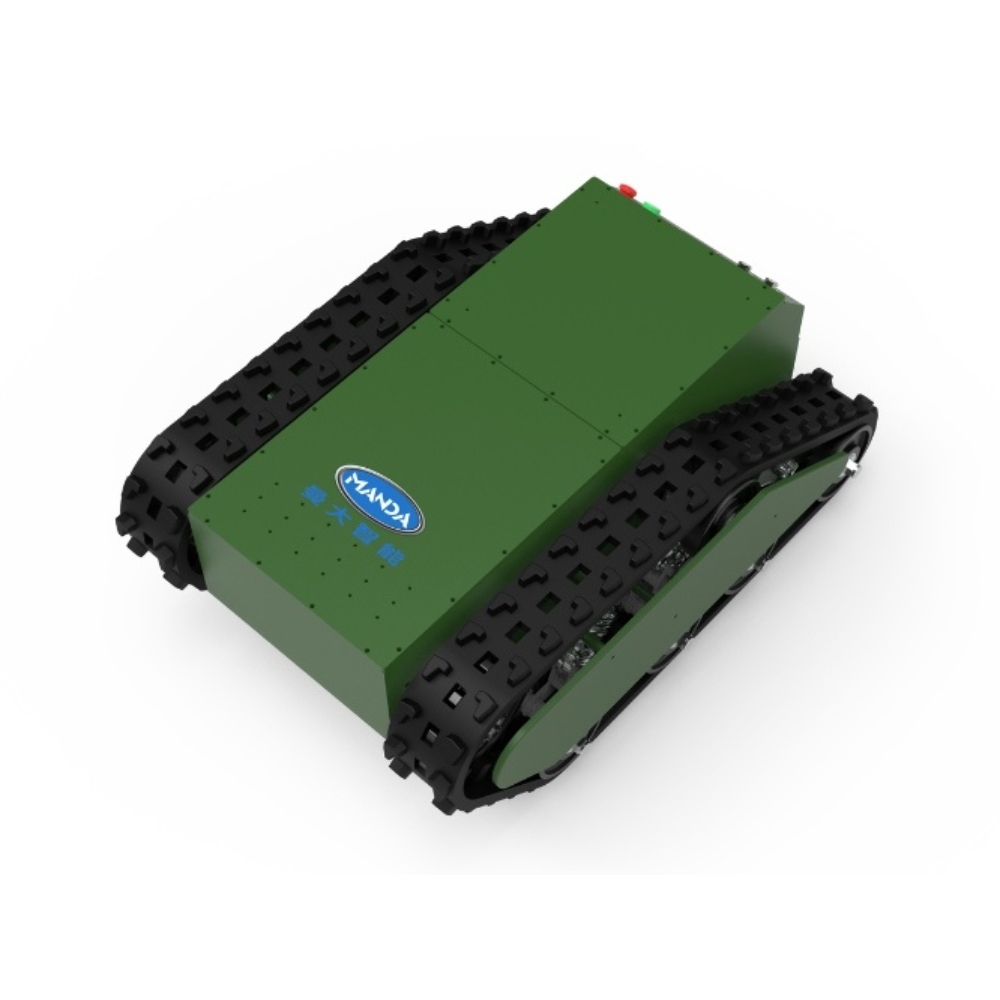

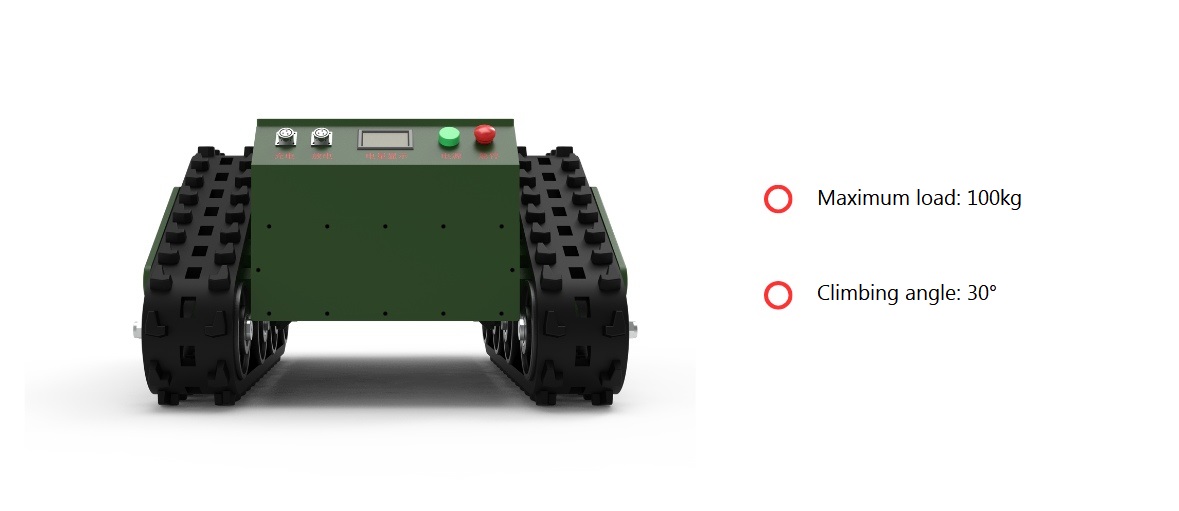

The RMP-D100 tanked robot platform has a rated load of up to 100kg, can climb slopes of 30°, and has a maximum traveling speed of 15km/h. The robot chassis is equipped with a standard CAN communication VCU, enabling users to carry out rapid secondary development. It can be widely applied in the integration and functional expansion of robot systems in industries such as scientific research and material transportation.

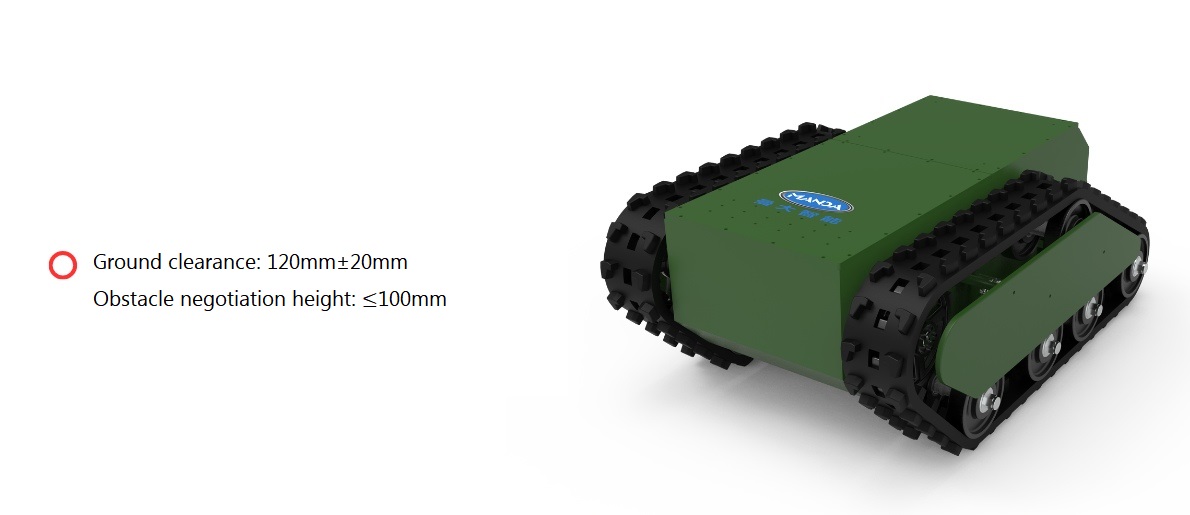

1. The ground clearance of the rc tank chassis is 120mm, and its obstacle-crossing capability is less than 100mm. The chassis width is 700mm, which enables it to easily pass through most narrow Spaces. The compact body and obstacle-crossing ability ensure its stable passage in complex environments.

2. It adopts a simple suspension structure design imitating the Matilda style. The track structure is made of lightweight materials, and the idler wheels are equipped with shock-absorbing springs, which can smoothly pass through all kinds of rough and complex roads, ensuring the stability of the vehicle body and the continuity of operation to the greatest extent.

3. The rc tank chassis is equipped with a high-torque servo motor, which has a fast response speed and a maximum speed of 15km/h, enabling it to complete designated tasks quickly and efficiently. It is also equipped with a built-in DC48V lithium iron phosphate battery, providing a battery life of 4 hours and supporting long-term operation.

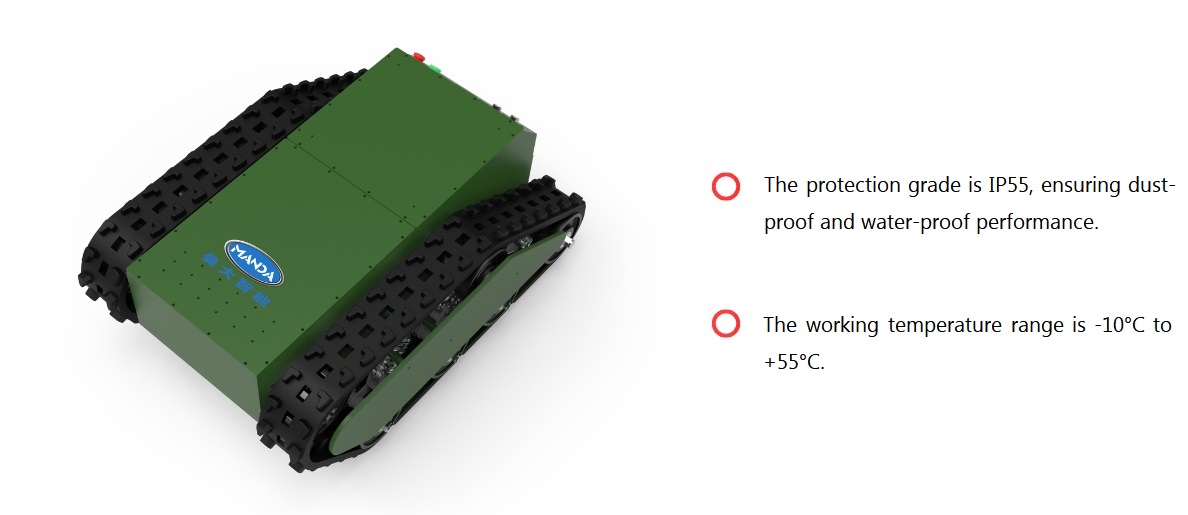

4. The chassis box part can be made of bulletproof steel plates to ensure that the internal control components are not damaged. Its operating temperature range covers -10°C to +55°C, and it has an IP55 protection rating, effectively achieving dust and water resistance, ensuring that the equipment can still operate stably in harsh environments.

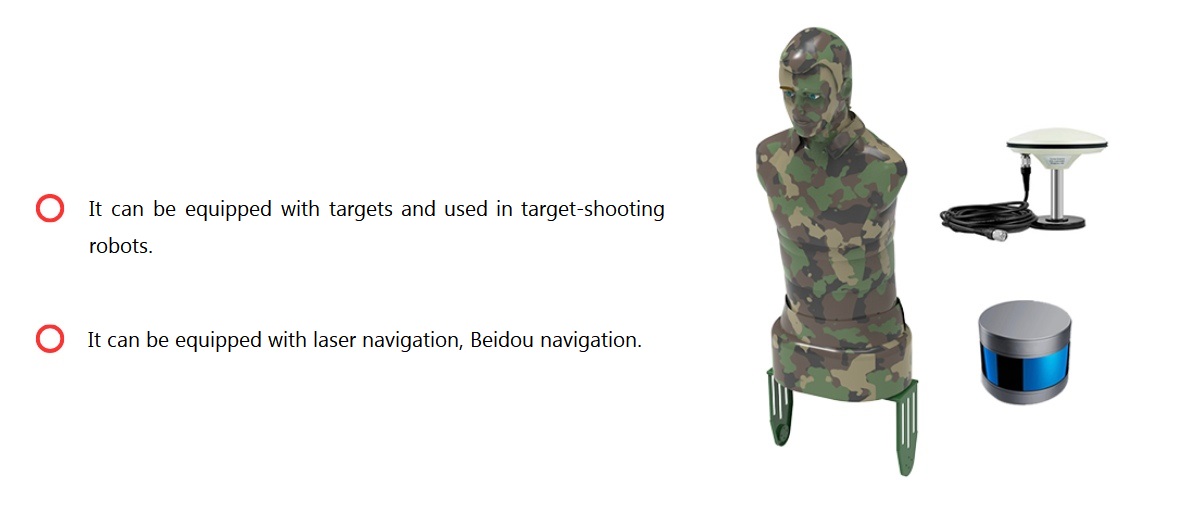

5. The chassis is equipped with a wealth of standardized interfaces, including the electrical part (DC48V output, DC24V output, standard CAN communication) and the mechanical part (connection to the cargo platform), which can flexibly adapt to the diverse needs of different users. The tank robot platform can be equipped with targets and is used for mobile target shooting robots. It can also be equipped with laser and Beidou navigation, providing multiple guarantees for achieving precise navigation and autonomous movement.

Parameters:

Description | Specification | Description | Specification |

Model | RDR-F100D-M3 | Steering type | 2WD differential type |

Dimensions | L1020×W710×H400mm±50mm | Total weight | 230kg±30kg |

Operating speed | 0~6km/h | Run time | 4h |

Obstacle negotiation height | ≤100mm | Climbing angle | 30° |

Ground clearance | 120mm±20mm | Maximum load | 100kg |

Turning diameter | 1300mm±100mm | Suspension type | The Christie style |

Track parameter | 37 links, 120mm wide | Track material | Rubber |

Explosive-proof grade | None | IP Grade | IPx5 |

Operation mode | Handheld remote control | Remote control distance | 50m(clear sight distance) |

Charging time | 3h (to reach 80% battery capacity ) | Charging | Manual |

Battery Parameter | DC48V lithium battery | Working temperature | -10℃~+55℃ |

Brake mode | Electromagnetic brake | Communication interface | CAN |

Navigation | It can be equipped with laser navigation, Beidou navigation. | ||

Application:

It is applicable to scenarios such as material transportation, fire emergency response, teaching applications, high-speed mobile target machine modification, and inspection vehicle modification.

Certificate:

To meet the diverse application requirements of customers and ensure the stability of product quality, our products have passed the ISO9001:2008 international quality management system certification and obtained multiple explosion-proof qualification certificates and test reports. Aimed at creating a reliable and stable product experience for you and facilitating efficient and safe production.

Advanced Equipment&Workshop:

In the R&D stage, mainstream simulation software is used to identify and prevent potential risks. In terms of quality control, a complete quality management system has been established, strictly implementing the full-process control from problem traceability to improvement closed-loop, and continuously promoting the PDCA cycle optimization. Through testing equipment such as aging test rooms, high and low temperature test chambers, and motion simulation systems, the stability and reliability of product quality are ensured.