What Is the Structure and Working Principle of Tracked Chassis?

The walking system of the track chassis is a core component of construction machinery and mobile robots, and its performance directly affects the passability, stability and operational efficiency of the equipment. This system is mainly composed of components such as tracks, drive wheels, idler wheels, guide wheels, track carrier rollers, tensioning devices, buffer springs and walking reducers.

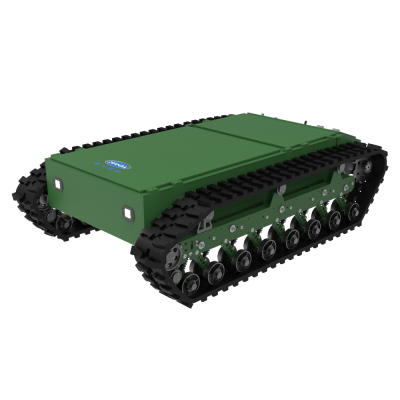

In terms of structural composition, the track, as a component in direct contact with the ground, is composed of track plates, main chain links, track chains, wear-resistant plates, etc. Track plates usually come with track spikes to enhance grip and are particularly suitable for soft or complex terrains. According to different materials, tracks can be divided into metal tracks and rubber tracks. Metal tracks have high strength and high traction. Rubber tracks have excellent grip and shock absorption effects. The drive transmits power to rotate the tracks, mainly through hydraulic motors or engines. The drive wheels mesh with the track chain of the tracks, which can effectively transmit torque. The idler wheels mainly serve to support the mass of the robot's chassis. By distributing pressure, they can reduce the wear and tear on the tracks and lower maintenance costs. Guide wheels are usually installed at a higher position and their main function is to guide the direction of the tracks and control the steering of the robot chassis. The track carrier roller supports the upper part of the track chassis to prevent frictional wear caused by track sagging. The tensioning device can adjust the tension of the tracks to prevent problems such as derailment and wear caused by overly tight or loose tracks. It is usually in the form of hydraulic tensioning or mechanical tensioning. The buffer spring can effectively absorb the ground impact and ensure the smooth running of the tracked robot chassis. The walking reducer is responsible for reducing the output speed of the hydraulic motor and increasing the output torque to meet the low-speed and high-torque working requirements of the track system.

In terms of working principle, the track chassis achieves movement through precise power transmission and mechanical coordination. The power comes from the engine or hydraulic pump and is transmitted to the walking reducer through the drive shaft or hydraulic pipeline. The walking reducer reduces the speed and increases the torque, driving the hydraulic motor or drive wheel to rotate. The driver drives the track chain to rotate. When the track plate rubs against the ground, frictional force can be generated, pushing the track chassis to complete the forward or backward movements. The steering action is accomplished by controlling the speed difference between the two tracks, such as decelerating or stopping one side.

In the walking system of the track chassis, the idler wheels, track carrier rollers and buffer springs work together to effectively absorb ground impacts and ensure the smooth operation of the chassis. The robot chassis independently developed by Manda Intelligent adopts a rubber track design and is equipped with a high-torque servo motor inside. Designed to imitate the simple suspension structure of the Matilda style, the support wheels are equipped with shock-absorbing springs to ensure the smooth passage of the equipment over complex road surfaces. Welcome to contact us at any time to get more solutions about robot chassis!