Maintenance Of Agricultural Machinery Navigation Equipment For Transplanters

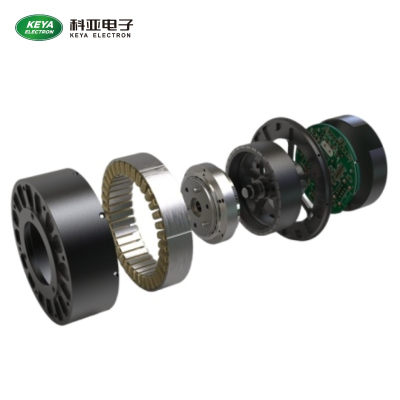

With the rapid development of precision farming, transplanters equipped with agricultural machinery navigation have become indispensable good assistants in field operations. Whether it is a large-scale farm that uses the equipment frequently or a farmer that uses it infrequently, scientific maintenance can extend the service life of the equipment. As the core of the navigation system, the stability of the auto steering motor is more directly related to the efficiency of farmland operations.

1. High-frequency-use rice transplanters

(1) Daily cleaning. After each day's use, the soil, weeds and other debris on the transplanter and navigation equipment should be removed in time to keep the surface of the equipment clean. Clean the machine with clean water and a dry towel to prevent equipment corrosion.

(2) Electrical system inspection. Check every day whether the power connection is stable, whether the voltage is stable, and whether there are any damages, aging, short circuits or other phenomena in the electrical circuits. If any of the above problems occur, they should be replaced or repaired in time.

(3) Functional testing. Before each day's operation, test whether the positioning accuracy, path planning function and autonomous driving function of the navigation system are normal, and whether the automatic steering motor responds quickly, in order to achieve precise steering of agricultural machinery equipment.

(4) Regular inspection. Regularly check whether the fasteners such as screws, wiring harnesses and joints are loose. Regularly inspect the connections of key components such as antennas and receivers to ensure they are tight and reliable.

2. Low-frequency-use rice transplanters

(1) Deep cleaning. Before and after each working season, the equipment should be thoroughly cleaned with a dedicated cleaner to ensure there is no dust or debris accumulated, and at the same time, to prevent rusting of the equipment.

(2) Comprehensive inspection of the electrical system. Before each use, a comprehensive inspection of the electrical system should be carried out to ensure that the equipment is free of faults.

(3) Comprehensive functional testing. Before each activation, all functions of the navigation system need to be verified one by one to ensure that all components of the system operate without any abnormalities.

(4) Long-term storage and maintenance. When agricultural machinery navigation equipment is not used for a long time, comprehensive maintenance, upkeep and inspection should be carried out.

(5) Start regularly. For equipment that has not been used for a long time, it is recommended to start it regularly to maintain the stability of its performance and eliminate the occurrence of potential failure risks.

Precautions:

(1) Safety first: Regardless of the frequency of use, when operating agricultural machinery navigation equipment, one should strictly follow the safety operation norms.

(2) Data backup: Regularly back up the data in agricultural machinery navigation devices to prevent data loss or damage.

(3) Professional training: Provide professional training for the operators of agricultural machinery navigation equipment to enhance their operational skills and equipment utilization efficiency.

Whether the transplanter is used at high frequency or low frequency, scientific maintenance can enable the navigation equipment of the transplanter to operate at its maximum efficiency. Jinan Keya is committed to providing high-performance power drive solutions for precision agriculture. Its core product, the hollow shaft interface unmanned driving auto steering motor, is specially designed to simplify installation and automatic steering control.

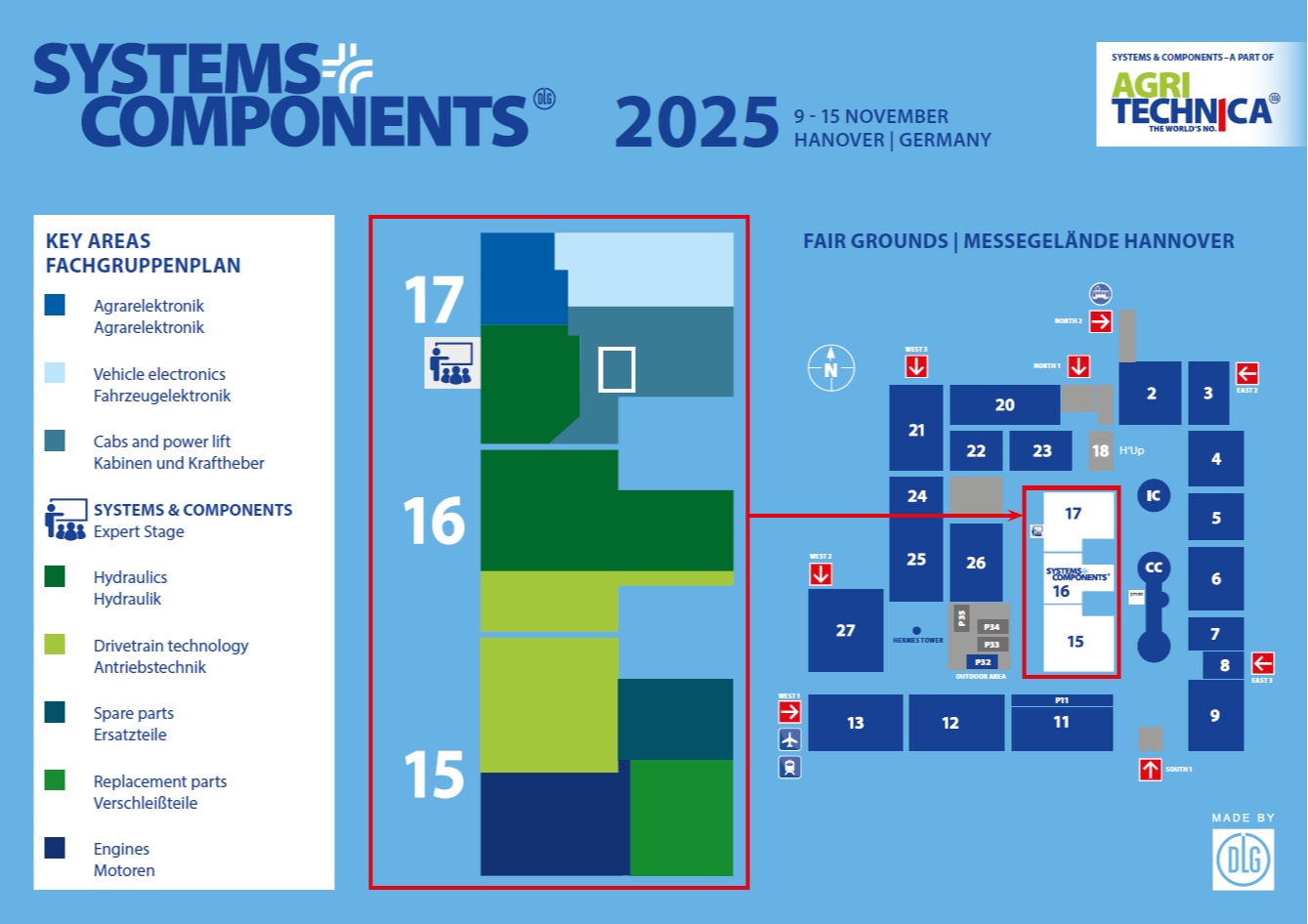

We will attend the AGRITECHNICA in Hannover, Germany from Nov. 9 to Nov. 15, 2025 at booth No.: 17F22b, welcome visit our booth.