What Should Be Noted When Using An Agricultural Machinery Navigation System?

In the transformation of modern agriculture, unmanned tractors and automatic navigation systems play a significant role. The key actuating component, the auto steering motor, is equipped with a high-precision encoder, which significantly improves control accuracy and response speed, further enhancing the efficiency of agricultural machinery operations. When agricultural machinery precisely execute steering instructions relying on gps tractor systems, the safety of automatic navigation products is the most important guarantee during the operation process.

Safety requirements for unmanned agricultural machinery and automatic navigation products

1. Electrical equipment should have protection functions against overcurrent, overvoltage, short circuit, momentary power supply changes and accidental reverse polarity connection. The interfaces should have anti-static functions.

2. When danger occurs or the autonomous driving system malfunctions (such as speeding, unexpected deviation from the guidance path, malfunction of the on-board control device, unstable voltage or guidance signal failure), its related actions should be immediately restricted or stopped to bring the autonomous driving system back within the controllable parameter range without creating new danger. At the same time, the malfunction of the autonomous driving system should not impede the use of manual operation.

3. All automatic functions of agricultural machinery navigation systems should only be operated through a separate operation controller. When the agricultural machinery navigation system is turned off, the automatic function should automatically return to the manual control state or the off state. At the same time, the operator should be able to undo the automatic function at any time, and the automatic function is only allowed to be restarted by the operator.

4. When the manual control function is used, the automatic control of the automatic navigation function should be automatically released. The connection of the electrical circuits in the agricultural machinery navigation system should also be correct and reliable to ensure there is no leakage.

5. Wires should be bundled, neatly arranged, firmly fixed, with firm joints and insulated sleeves. Insulating sleeves should be installed when wires pass through holes. The layout of electrical circuits should avoid friction and contact with heat-generating components.

6. Operators are strictly prohibited from getting on or off the vehicle during the autonomous driving process. When in the automatic navigation mode, one should always observe the obstacles ahead and assess potential dangers. At the same time, operators are prohibited from driving while fatigued.

Inspect the assembly and appearance quality

1. All components should be securely assembled without any looseness, and be easy to adjust. The operation of the controller's switches and buttons should be sensitive.

2. The surfaces of all components should be smooth and clean, free of obvious scratches, abrasions, burrs and other mechanical damages. The coating and plating should be smooth and of uniform color.

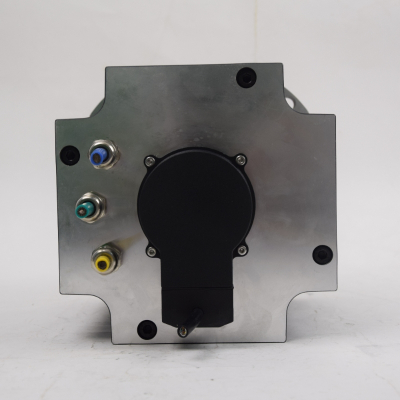

In the wave of precision farming, safety and reliability are the foundation of all agricultural machinery operations. Jinan Keya focuses on the research and development of automatic steering motors for tractors. It adopts an integrated design of motor and driver, which is compact in size. Meanwhile, the hollow shaft interface design makes it convenient to connect and install with the steering wheel. The steering motor is equipped with multiple built-in protection functions, providing safety guarantees for the automatic steering system of agricultural machinery, improving the operational efficiency of tractor equipment, and reducing the workload of drivers at the same time.

We will attend the AGRITECHNICA in Hannover, Germany from Nov. 9 to Nov. 15, 2025 at booth No.: 17F22b, welcome visit our booth.