What Is the Function of the Chassis in an Agricultural Robot?

In the wave of traditional agriculture's transformation towards intelligence and precision, agricultural robots are gradually becoming the new main force in field management. Among them, the four wheel chassis, as the "carrying platform" of the robot system, is not only the foundation for achieving movement and operation, but also the key to determining whether the entire agricultural robot can adapt to complex environments and efficiently complete diverse tasks.

Especially in the face of the current practical pain points such as non-standard ridge spacing in agricultural planting areas, diverse crop types, and inconsistent agricultural machinery, the robot chassis not only needs to be flexible and compatible with various agricultural tools, but also must work stably in various terrains and crop environments. This is precisely the core value that the modularly designed 4wd mobile platform can offer.

1. Flexible adaptation and stepless adjustment

Traditional agricultural machinery often has fixed wheel track and wheelbase, making it difficult to adapt to the planting patterns of different crops. The wheel track of the four-wheel four-steering chassis is adjustable, ranging from 900 to 1200mm. The wheelbase can be freely adjusted between 850 and 1350mm. Users can manually adjust the wheel track and row spacing according to the actual planting ridge spacing, which significantly improves the utilization rate of the equipment and the operation accuracy.

2. Three steering modes precisely control the movement posture

In addition to adjustable wheel track and wheelbase, this chassis also supports three movement postures: lateral movement, Ackman steering and pivot steering. These three postures can be freely switched, enabling the agricultural robot to operate flexibly even in complex terrains.

3. Strong scalability, multi-functional in one device

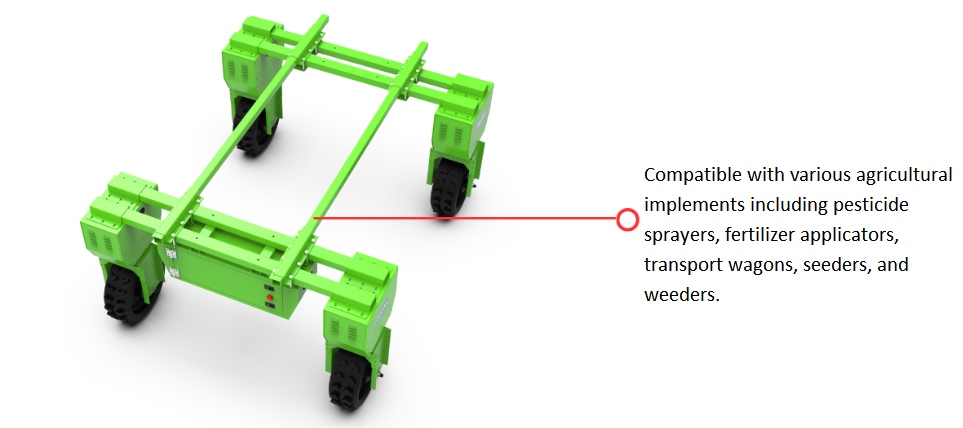

There are various types of agricultural operations, ranging from sowing, fertilizing, spraying pesticides to weeding and transportation, which often require the coordination of different tools. This four wheel chassis adopts modular upper design to reserve sufficient structural space, which can quickly carry a variety of agricultural tools such as spray machine, fertilizer machine, seed planter, transporter bucket and so on. According to the actual agricultural needs, tools are matched to significantly reduce the cost of mechanical procurement and increase the utilization rate of equipment.

4. Built-in VCU, supporting driverless applications

High-torque hub motors and steering motors with reducers are selected, both equipped with encoders, ensuring the accuracy of power output and enabling the robot to walk smoothly even under load. The wheeled chassis is equipped with a built-in VCU, which can be easily matched with an unmanned driving control system. It also reserves standard interfaces, supporting multiple navigation methods such as laser navigation, Beidou navigation, and follow navigation. Users can flexibly choose according to their actual scenarios to quickly build an efficient and stable unmanned operation system.

From field plant protection operations to mechanized operations in vegetable greenhouses, from mechanized transformation of orchards to the renovation of unmanned farm projects, this modular intelligent mobile robot chassis is redefining the way modern agriculture operates. It can not only adapt to various farmland operation environments and crop planting patterns, but also carry 300kg of goods and travel at a speed of 10km/h. It features stable driving and superior expansion performance, significantly enhancing operational efficiency and the utilization rate of the robot chassis, providing a solid foundation for the development of smart agriculture.