What Is the Wheeled Chassis of a Robot?

The chassis not only determines the robot's movement capability, but also directly affects its functional upper limit and application boundaries. With the increasing complexity of scene demands, a wheeled robot chassis with strong mobility and operational flexibility is becoming a key support for the intelligent upgrade of the industry.

1. Four forms of movement, flexibly breaking through spatial limitations

The RMP-WL100 wheeled robot chassis allows for free switching among four motion modes (lateral, diagonal, Ackermann, and pivot steering). It can easily handle various scenarios such as narrow factory roads, between warehouse shelves, and hard outdoor roads. It can be combined with multi-level obstacle avoidance solutions to effectively avoid collision risks.

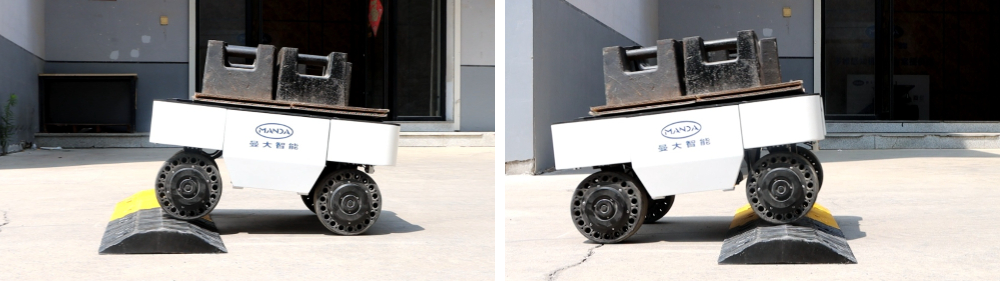

2. Independent suspension system empowers smooth movement

The 4-wheel independent double wishbone suspension system effectively absorbs road vibrations, ensuring vehicle stability even in complex terrains while protecting the upper load equipment. The 4 wheel chassis has a rated load capacity of 100kg and can easily pass through obstacles of 50mm. When fully loaded, it has a climbing ability of 15°. At the same time, the vehicle lights can clearly display the operating status of the chassis.

3. Open Development Interface

It is equipped with an internal VCU control unit and a standardized CAN communication protocol, allowing users to quickly achieve secondary development and functional expansion. Reserve standard interfaces to support flexible assembly of the upper load of the robot chassis, significantly shortening the cycle from development to implementation of robot projects.

4. Safe and reliable, unafraid of harsh challenges

The wheeled chassis has been tested in many extreme environments, such as vibration and jolt, high and low temperature, rain and so on. Its stability, reliability and durability have been fully verified in various environments. Whether it is a vibrating factory workshop, an outdoor environment exposed to wind and sun, or a low-temperature cold chain environment, it can maintain a stable and reliable operating state, ensuring the efficient and continuous operation process.

5. Quick-detachable battery design

The chassis is equipped with a DC48V30Ah lithium iron phosphate battery pack, offering a range of up to 6 hours, meeting the demands of the vast majority of operational tasks. It adopts a quick-detachable battery design to fully ensure the continuous operation requirements. The wheeled robot chassis integrates two flexible charging modes, manual and automatic, allowing for flexible selection based on actual application scenarios to ensure that the equipment maintains high working efficiency in different work processes.

Application scenario example

Intelligent inspection: The wheeled chassis can be equipped with cameras and sensors and other devices to assist manual labor in conducting intelligent inspections in industrial parks, orchards, etc.

Industrial transportation: The rated load capacity of the chassis is 100kg, which can transport goods in factories and warehouses, reducing labor costs and improving overall logistics efficiency.

Education and research: Provide high-performance remote control platforms for universities or research teams to assist teaching. Through on-site real-time display of the motion control of the robot chassis, deepen students' understanding of the principles of the robot system.

Special operations: For special robot fields such as fire protection and security, the chassis with built-in VCU is subject to secondary development and functional expansion to endow it with core operation capabilities in complex scenarios.

The RMP-WL100 wheeled chassis redefines "the chassis of robots" with four motion forms, high load capacity and high reliability. It is not only the foundation for the stable movement of robots, but also the key driving force for achieving intelligent scenarios. From intelligent inspection to industrial transportation, from the transformation of special robots to scientific research and teaching, four wheel chassis are providing the strongest mobile support for the intelligent upgrade of all industries.